Sound Proofing

How does sound travel?

Sound travels through the air like ripples on a pond surface when a stone is dropped into it. The sound radiates outwards in all directions from the source, gradually reducing in intensity or until an object stops its progress.

Sound (dB Decibels)

Sound is described in different ways but primarily in terms of intensity and frequency. The sound intensity is described in dB. A low dB indicates a soft sound, a high dB value indicates a loud sound.

Frequency describes how high or low pitched the sound is (Hz).

Sound Reduction

A stereo’s volume set at 60dB decreased by…

-3dB is just perceptible

-5dB clearly noticeable

-10dB Half the original volume

Recommended Indoor Ambient Noise Levels

Dwellings:

- Bedrooms 30-35dB

- Living rooms 30-40dB

Offices:

- Private 35-40dB

- Open plan 45-50dB

Typical noise levels

50 metres overhead aircraft 140dB

Car alarm 120dB

Passing train 90dB

20 metres from busy carriageway 78dB

20 metres from busy main road 68dB

Keeping sound in - 70% of people admit to feeling harassed by noise

Loud music remains the main source of noise complaints in England, Scotland & Wales, while in Ireland almost 70% of complaints emanate from road noise in homes, hotels and apartments in busy thoroughfares! Secondary glazing is an excellent solution for Hotels, Pubs & Clubs or factory’s close to housing to keep noise in.

New Glass Technology

Acoustic laminated glass (Silence) is the latest product to come onto the market. Two sheets of glass are bonded together with a 0.76mm thick layer of special acoustic polyvinyl butyral (PVB). Solaglas estimate a 20% improvement over standard glass. Taking this increase into account when installed into our secondary glazing a reduction of 44-45dBs should be easily achievable.

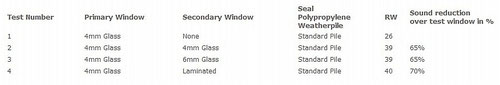

Sound reduction test

A three panel horizontal sliding secondary glazing unit (1960mm x 1190mm High) was sent to the Building Research Establishment in Watford for testing

How was the test carried out?

A cavity wall was built into the aperture between two rooms of the BRE transmission suite to the following specification

Block thickness 100mm

Block density 1800 kg/m2

Cavity spacing 75 – 80mm

Finished with plasterboard on dabs.

An aperture was left in the wall to house the window. A typical Georgian window from a Builders Merchant with three openers was fitted.

The secondary was installed behind the window on timber liners to provide a minimum pane spacing of 100mm. The condition of the primary window will have an effect on the overall system performance.

The Facts on Sound Proofing

‘`Where high sound insulation of windows is required, airspace of widths of greater than 100mm may be required with one glass width being of a greater thickness than the outer pane (if fitting inside a double glazed window). However beyond 200mm the improved acoustic value is small. Increasing the width of the cavity between the primary window pane and inner pane increases sound insulation - (ensure that the component glasses differ in thickness by at least 30% - e.g. 4mm + 6mm or 6mm + 4mm. Fitting of absorbent materials to the reveals is beneficial as it reduces reverberation in the cavity’’.

(Ref: BRE Sound Insulation Of Glazing Systems Paper IP12/89’’).

Over the usual cavity width range of 6mm to 20mm or more for double or triple glazed insulated units, there is little variation in acoustic performance (4%). With Secondary Glazing the acoustic performance is enhanced greatly by creating the optimum ‘air gap’ (100mm – 150mm) between the existing glass and the inner glass.

Combine this process with fitting an absorbent frame onto walls, overhead reveals and window sill area. This will reduce potential reverberation from walls and cavity area of the windows.

When fitting Secondary Glazing Systems it is advisable to use a different glass thickness to the one in the existing window. From an ‘energy saving’ point the ‘U’ value of single pane glazing would be between 5-7 and fitting of Secondary Glazing will reduce this to between 1.6 and 2.4, depending on existing window quality, which would be similar or better than a conventional 12 – 16mm vacuum sealed double glazed unit. Gas filled systems would be more energy efficient.

The information supplied herein is a general description of the WIND-DO SEAL System – its products and materials and WIND-DO SEAL Ltd hereby disclaims all liability howsoever arising from any error in or omission from this information and any consequences of relying on it.

The Secondary Glazing

& Flyscreen Experts

The Secondary Glazing

& Flyscreen Experts